almatjr.html cinemana.html cinemana_shbkty.html cinemana_tanzel.html Descargar-Play-Store-APK.html matjr_play.html matjr_tanzel.html matjr_update.html mtgr.html noon.html noon-codes.html noor.html noor_nezam.html noor_ntayg.html noor_pass.html noor_reg.html play-store-download.html play_down.html play_go.html play-en.html soq_ply.html t7mel_play.html tanzel_play.html whats_tanzel.html whats_web.html whts_tanzel.html whts_web.html

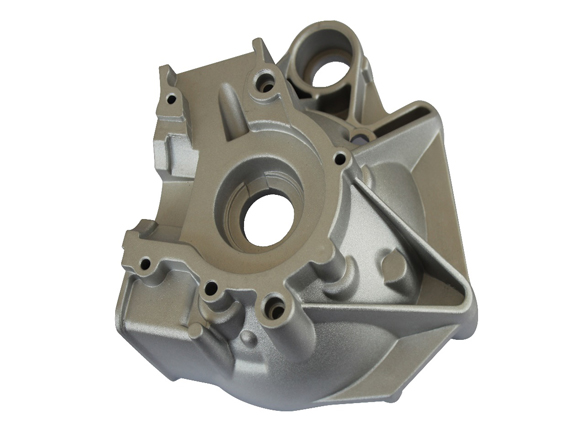

What Is Aluminum Die Casting

What Is Aluminum Die Casting

Aluminum die casting is a versatile manufacturing process for producing engineered metal parts by forcing molten metal into a mold form due to high-pressure systems. china mold It’s a manufacturing process for producing precise, accurately smooth, and textured metal parts. The parts with the highly valued combination of lightweight and superior strength. The aluminum die-casting machines range from 18-0T to 2000T so that we can produce parts with a few grames to more than 40 pounds.

Even aluminum die casting parts can with different surface treatments, such as powder coating, plating, e-coating,chrome plating, and bright polishing, with a beautiful and protected outer layer.

Why choose aluminum die casting

Aluminum with advantages such as lighter weight, durable and so on, aluminum also is one of the most popular materials for producing functional parts and prototypes. It also offers impeccable corrosion resistance, thermal and electrical conductivity, and also maintains dimensional stability even in high temperatures and harsh environments.

Since this material with a high melting point, so aluminum die casting process is the best way to cast aluminum parts

In a detail of this metal casting process, high pressure is used to force molten metal into the mold cavity. So aluminum die casting requires to use of aluminum die casting mold, which with a mold cavity, or cavities, which is created using two hardened tool steel dies that are machined into a specific shape, are machined into a special shape.

Compared to CNC machining, aluminum die casting reduces the amount steps required for production and prototyping, resulting in lower manufacturing costs. It also ensures a high-quality surface finish and precise dimensional consistency.

This technique is especially advantageous in small and middle-size casting parts, it's widely used in industries such as automotive, lighting, medical and more.

Advantage of aluminum die casting

As a lightweight metal, the most popular reason for utilizing aluminum die casting is that it creates very lightweight parts without sacrificing strength. Aluminum die-cast parts also have more surface finishing options and can withstand higher operating temperatures than other non-ferrous materials. Aluminum die-cast parts are corrosion resistant, highly conductive, have good stiffness and strength-to-weight ratio. The aluminum dies casting process is based on rapid production that allows a high volume of die casting parts to be produced very quickly and more cost-effectively than alternative casting processes. Aluminum die casting has become the favored option for buyers worldwide.

Characteristics and Advantages of Aluminum Die Castings include:

·Have a good stiffness and strength-to-weight ratio

·Based on rapid production

·Allows a high volume of die casting parts to be produced very quickly

·Is more cost-effective than alternative casting processes

·Lightweight and Durable

·Good strength-to-weight Ratio

·Great Resistance to Corrosion

·Excellent Electrical Conductivity

·High recyclability

Custom die casting auto parts